CONTACT

E-mail: info@vst-display.com

TEL: 0086-13360078105

4. FSTN technology

FSTN is a film-compensated STN, which eliminates partial dispersion and can realize black-and-white display, so it is called black-and-white mode. The basic principle is to add a layer of polymer film to the STN structure to compensate for the phase difference of the liquid crystal layer. Compared with STN, it has higher contrast and wider viewing angle range.

The retardation of the liquid crystal is 830~890nm, the twist angle is 180~270 degrees, the viewing angle is -30~50 degrees up and down, the left and right viewing angles can reach -40~50 degrees, and the response time is about 230~300 milliseconds. The contrast is around 5. It can be applied to the drive with the number of drive channels below 240, and can realize the display of dot matrix and segment code.

Products can be applied to various industrial and consumer electronics categories, such as digital display modules, numerical control equipment, communication equipment, instrumentation, medical equipment, elevators, white goods, small household appliances and other products.

a) Postive mode

Black fonts on white background.

b) Negative mode, backlight is needed.

White fonts on black background.

5. FFSTN technology

FFSTN, the double-layer polymer compensation mold is applied to STN, and the contrast and viewing angle range are further improved on the basis of FSTN.

The retardation of the liquid crystal is 830~890nm, the twist angle is 180~270 degrees, the viewing angle is -30~50 degrees up and down, the left and right viewing angles can reach -40~50 degrees, and the response time is about 230~300 milliseconds. Used in 240 duty or less to drive, dot matrix products, can realize the black and white display of any text and pattern.

Products can be applied to various industrial and consumer electronics categories, such as industrial control equipment, high-end home appliances, automotive instruments, etc.

a) Positive mode.

The double-layer compensation film is added to the single-sided polarizer, and it is displayed as black fonts on a white background. Contrast up to 10.

b) Negative mode. Backlight is needed.

The upper and lower two layers of polarizers with compensation touches are used to further improve the contrast and viewing angle range on the basis of FSTN, display white characters on a black background, and negative display products are characterized by very black background and high contrast, up to 10-20.

Also, it can achieve more display performance by using different colors LED backlight.

6. ASTN technology

ASTN products are ultra-wide viewing angle liquid crystal film compensation STN products, which have the advantages of high contrast, wide viewing angle and temperature compensation, and are suitable for the needs of image shape industrial control and vehicle-level products. There are two modes: black text on a white background and white fonts on a black background. Such products are mainly used in industrial control and automotive products with high requirements, such as car air conditioners, electric meter screens, industrial control instruments, car audio screens, etc.

a) Positive mode

Can achieve ultra-wide viewing angle (60 degrees up, down, left and right), high contrast (up to 10), high durability (working: -30 to 80 degrees, storage: -40 to 90 degrees), high and low temperature working background color changes Small features, generally used in products within 240 channels of drives.

b) Negative mode. Backlight is needed.

It can achieve ultra-wide viewing angle (60 degrees up, down, left, and right), high contrast (Up to 50), high durability (-40 degrees to 90 degrees), black background, low temperature and low temperature changes, general Used in products within 240 duty drives.

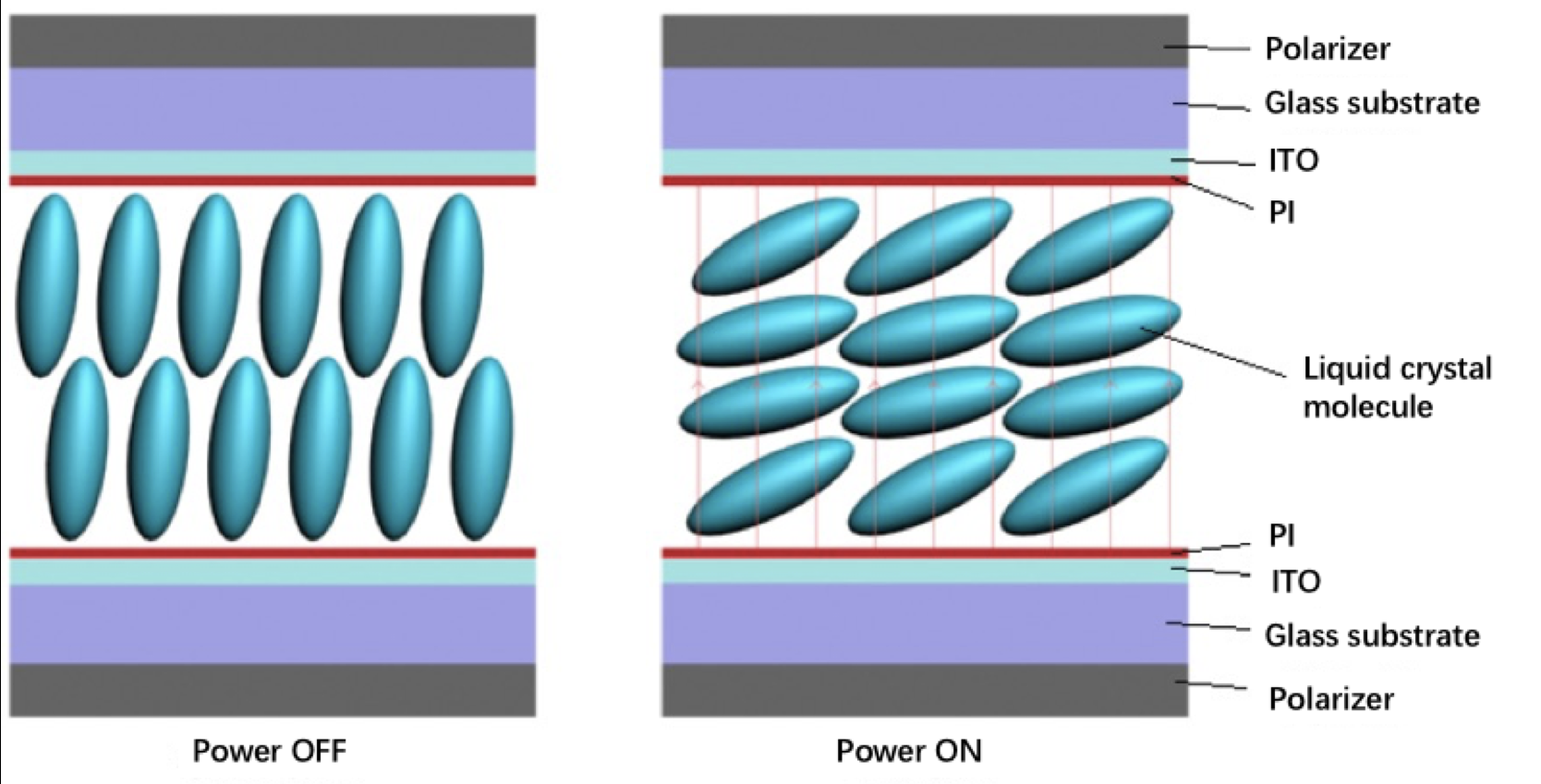

7. VA technology

VA technology, it is short for Vertical Alignment technology.

The liquid crystal molecules are perpendicular to the upper and lower substrates and sandwiched between the two electrode substrates to form a liquid crystal cell. The upper and lower polarizers are perpendicular to each other; the light generated by the backlight becomes linearly polarized light through the lower polarizer and enters the liquid crystal cell without being distorted. Cannot pass through the upper polarizer, forming opaque. When a certain voltage is applied between the two electrodes, the liquid crystal molecules rotate and tend to be parallel to the substrate, so that the light enters the polarized light generated in the liquid crystal cell through the upper polarizer of the upper glass substrate, and then passes through the lower polarizer (in the direction of the upper polarizer is vertical) to form light transmission.

Different from TN/STN technology, the liquid crystal molecule is standing vertically when power off. By which, VA LCD can achieve pure black background color and super high contrast ratio of 500 to 2000.

Mainly used in all kinds of automotive, industrial and electronic, consumer products, especially in home appliances, industrial control, automotive products have a broad market, can be widely used in air conditioning screens, elevator screens, industrial control screens, instruments, players, counters, industrial Controller, car audio, etc.

a) Normal viewing angle.

Based on the principle of vertical orientation of the product, with backlight, high contrast can be achieved, which can up to 1000, black

background and high reliability performance (working: -30~80 degrees, storage: -40) ~90 degrees), the viewing angle can reach (the

viewing angle is 40 degrees up, down, left, and right), and it can be visible in the sun;

b) Full viewing angle.

Based on the principle of vertical orientation of the product and the principle of orientation by making patterns on ITO, with backlight, full viewing angle can be achieved: viewing angle can reach (the viewing angle is 80 degrees up, down, left and right), high contrast: it can up to 1000, the background color is black and highly reliable performance (working: -30 to 80 degrees, storage: -40 to 90 degrees), and can be visible in the sun.

CONTACT

E-mail: info@vst-display.com

TEL: 0086-13360078105